Archives: Tools

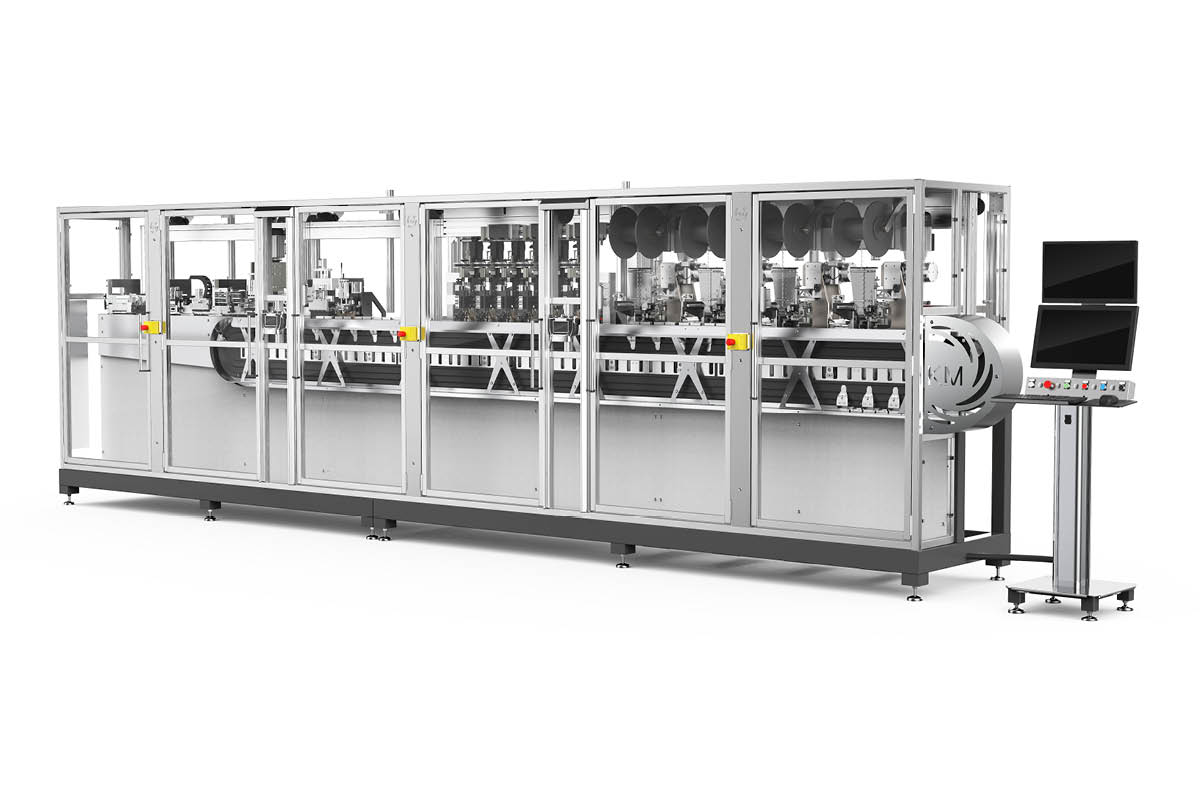

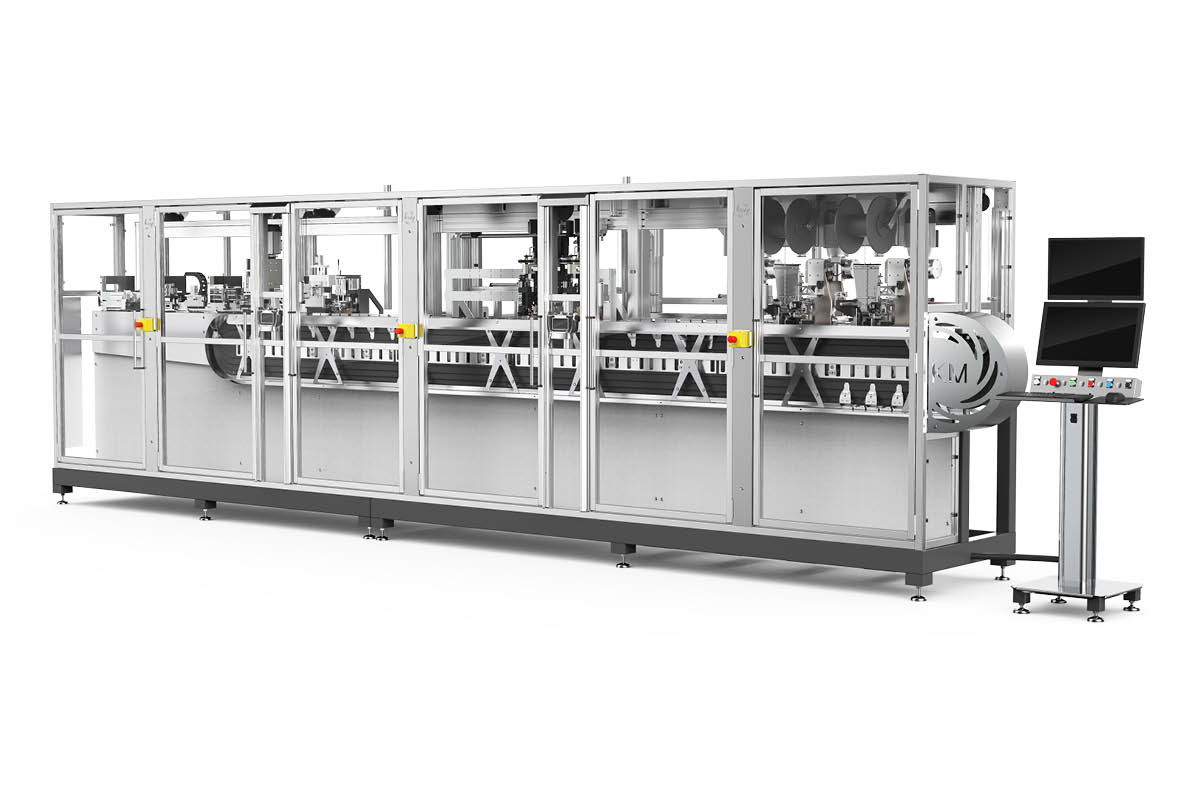

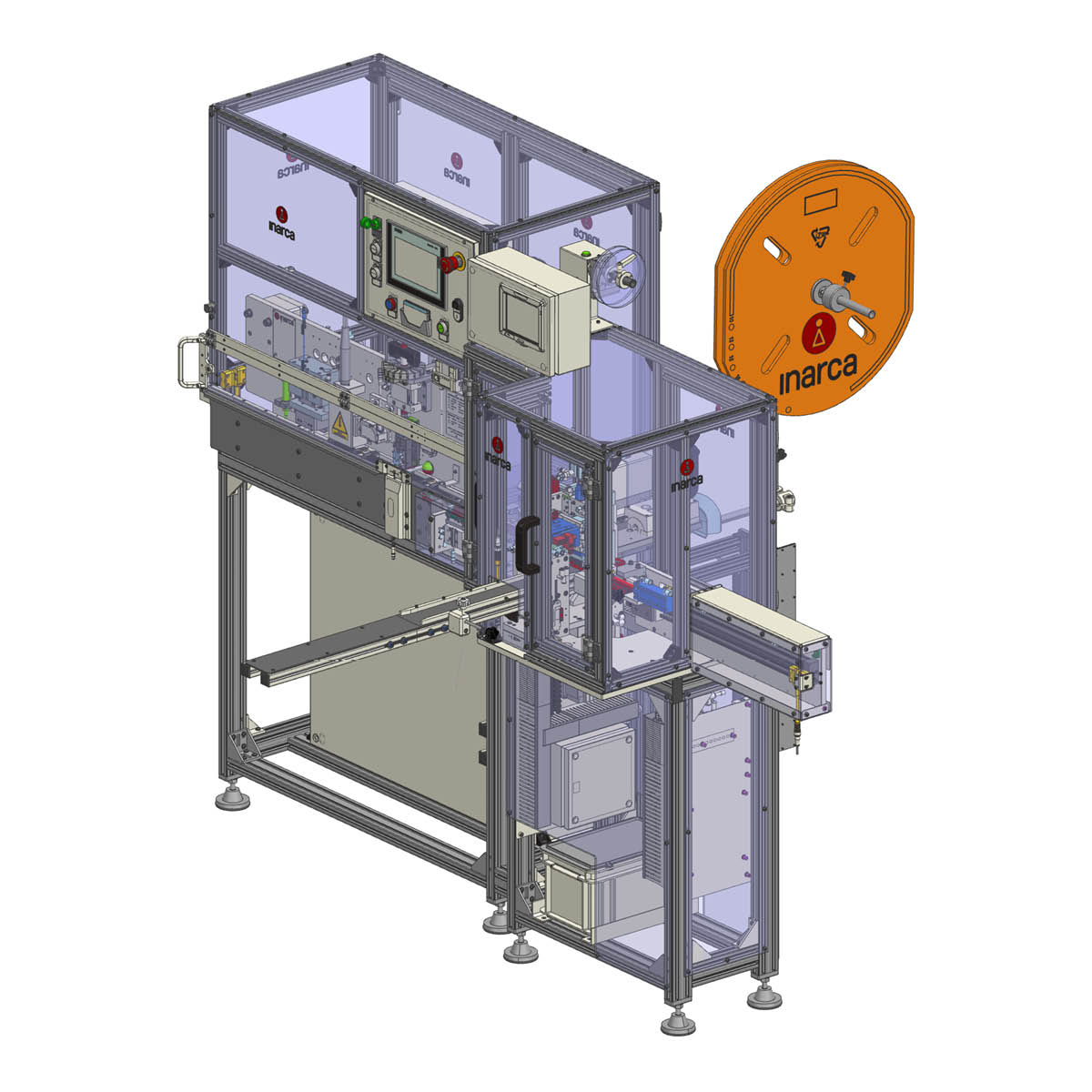

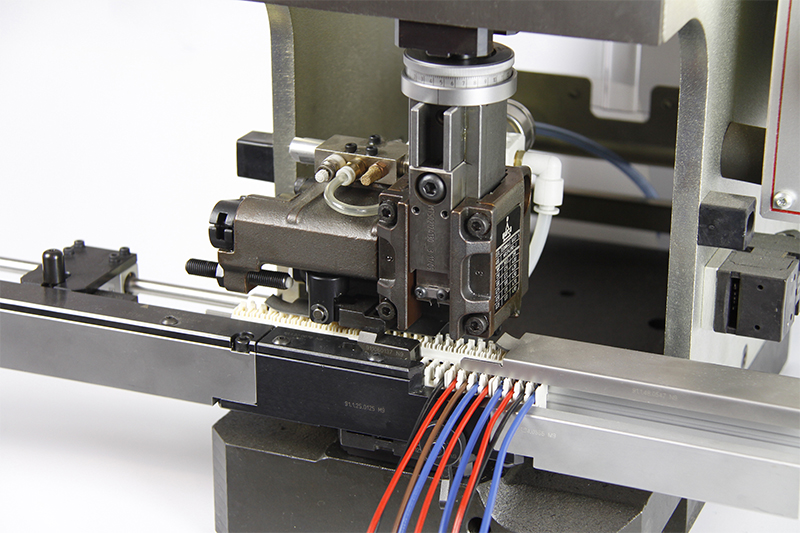

Automatic-semiautomatic machines, mini applicators and tools to process IDC connectors

Automatic-semiautomatic machines, mini applicators and tools to process IDC connectors

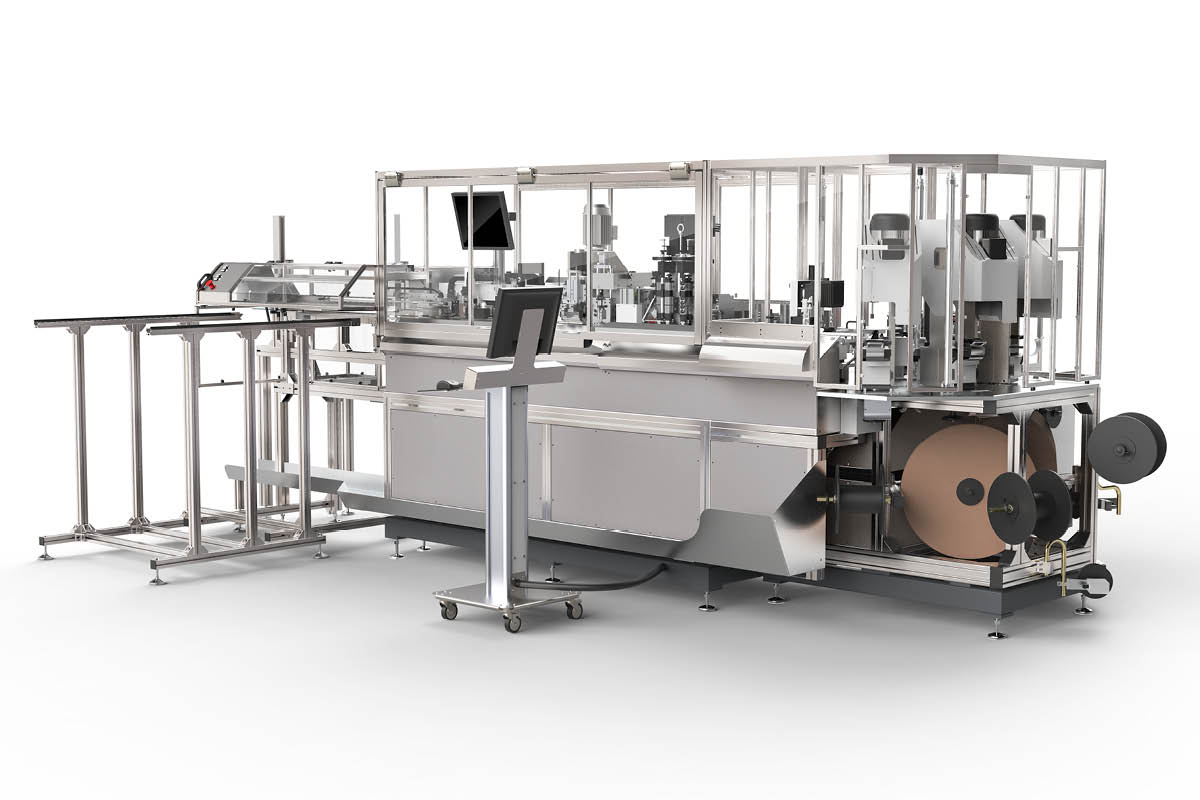

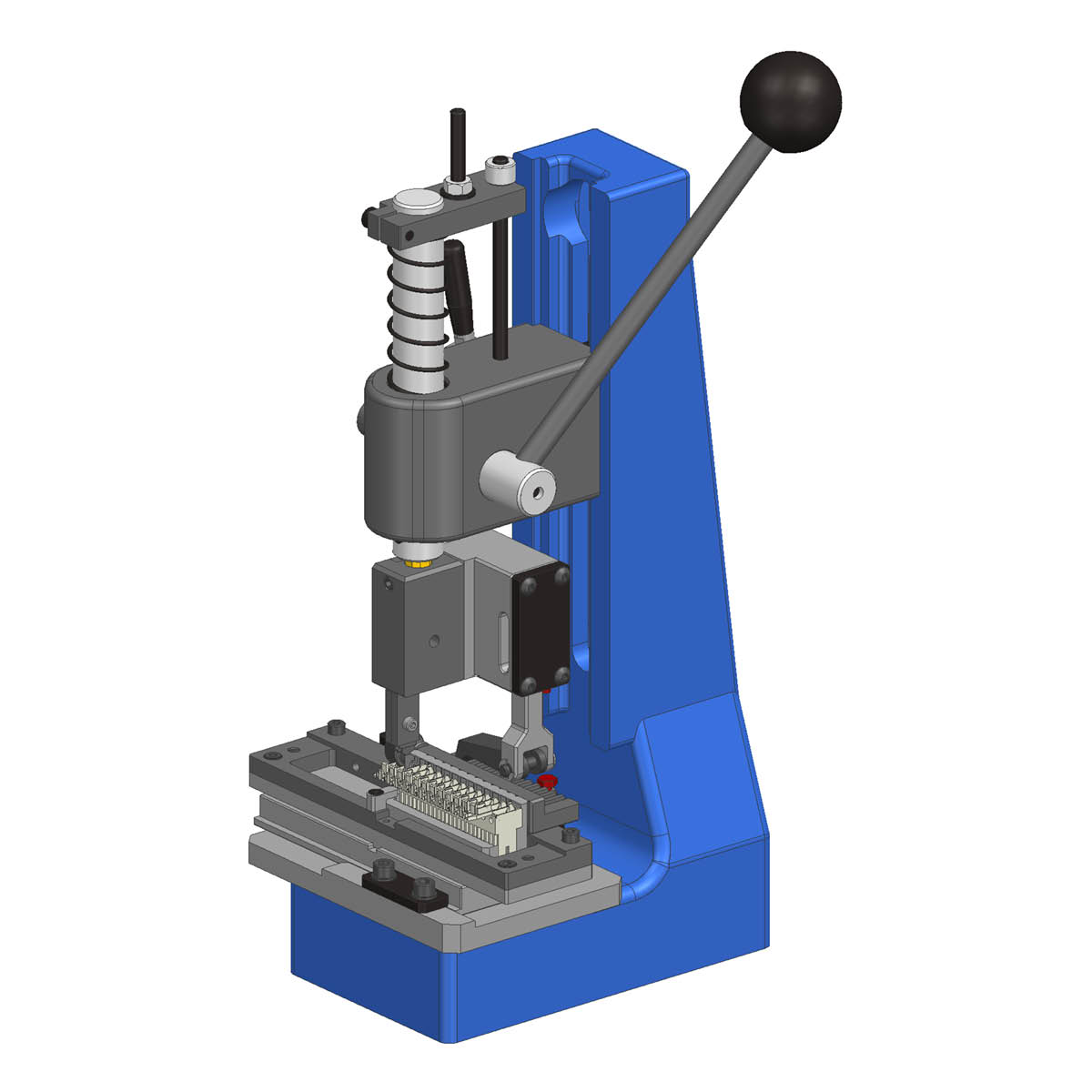

Machines, Insertion Units and manual presses for inserting INAR-RS and INAR-RS MATE terminals

Machines, Insertion Units and manual presses for inserting INAR-RS and INAR-RS MATE terminals

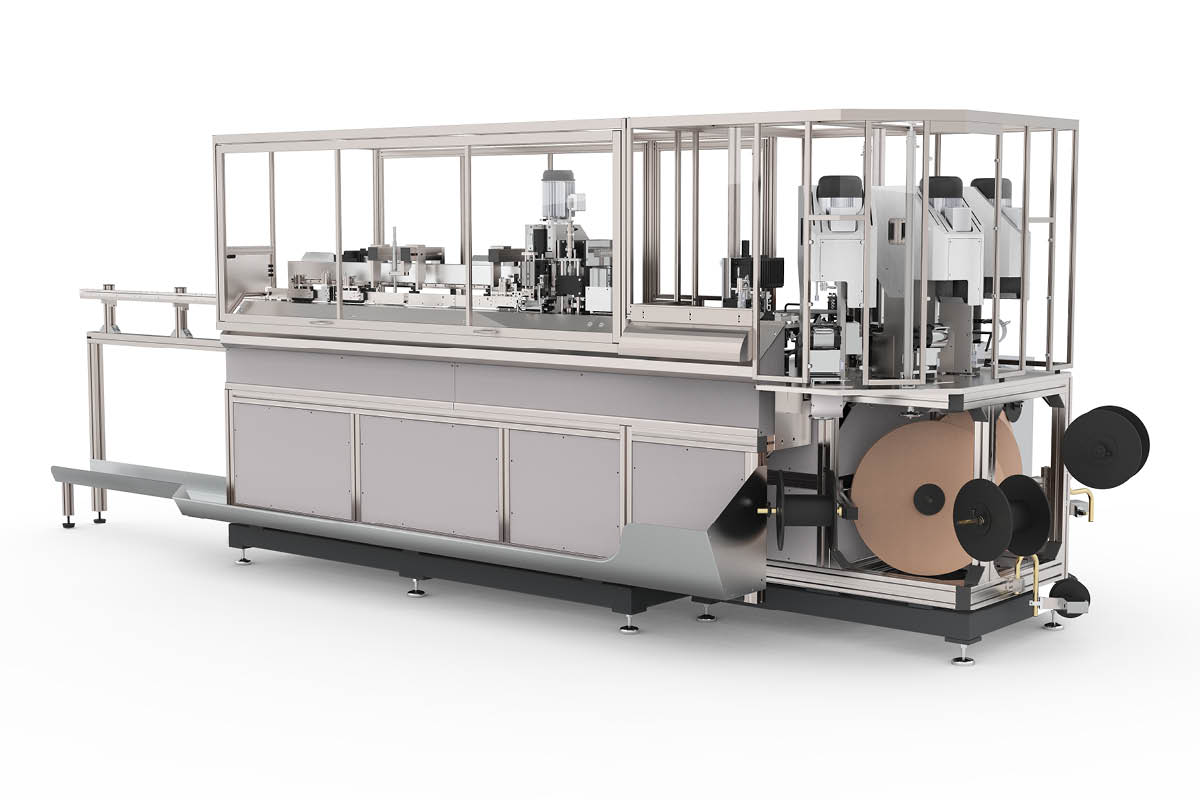

Machines, applicators and tools for crimping both cables with insulation and magnet wire

Machines, applicators and tools for crimping both cables with insulation and magnet wire

Tooling

IDC

INAR-IDC RAST connectors

IDC

INAR-IDC RAST connectors

Automatic-semiautomatic machines, mini applicators and tools to process IDC connectors

Automatic-semiautomatic machines, mini applicators and tools to process IDC connectors

INAR-RS

INAR-RS terminals

INAR-RS

INAR-RS terminals

Machines, Insertion Units and manual presses for inserting INAR-RS and INAR-RS MATE terminals

Machines, Insertion Units and manual presses for inserting INAR-RS and INAR-RS MATE terminals

CRIMP

Crimping terminals

CRIMP

Crimping terminals

Machines, applicators and tools for crimping both cables with insulation and magnet wire

Machines, applicators and tools for crimping both cables with insulation and magnet wire

Tooling

IDC

INAR-IDC RAST connectors

IDC

INAR-IDC RAST connectors

Automatic-semiautomatic machines, mini applicators and tools to process IDC connectors

Automatic-semiautomatic machines, mini applicators and tools to process IDC connectors

INAR-RS

INAR-RS terminals

INAR-RS

INAR-RS terminals

Machines, Insertion Units and manual presses for inserting INAR-RS and INAR-RS MATE terminals

Machines, Insertion Units and manual presses for inserting INAR-RS and INAR-RS MATE terminals

CRIMP

Crimping terminals

CRIMP

Crimping terminals

Machines, applicators and tools for crimping both cables with insulation and magnet wire

Machines, applicators and tools for crimping both cables with insulation and magnet wire

Tooling

IDC

INAR-IDC RAST connectors

IDC

INAR-IDC RAST connectors

Automatic-semiautomatic machines, mini applicators and tools to process IDC connectors

Automatic-semiautomatic machines, mini applicators and tools to process IDC connectors

INAR-RS

INAR-RS terminals

INAR-RS

INAR-RS terminals

Machines, Insertion Units and manual presses for inserting INAR-RS and INAR-RS MATE terminals

Machines, Insertion Units and manual presses for inserting INAR-RS and INAR-RS MATE terminals

CRIMP

Crimping terminals

CRIMP

Crimping terminals

Machines, applicators and tools for crimping both cables with insulation and magnet wire

Machines, applicators and tools for crimping both cables with insulation and magnet wire

Tooling

IDC

INAR-IDC RAST connectors

IDC

INAR-IDC RAST connectors

Automatic-semiautomatic machines, mini applicators and tools to process IDC connectors

Automatic-semiautomatic machines, mini applicators and tools to process IDC connectors

INAR-RS

INAR-RS terminals

INAR-RS

INAR-RS terminals

Machines, Insertion Units and manual presses for inserting INAR-RS and INAR-RS MATE terminals

Machines, Insertion Units and manual presses for inserting INAR-RS and INAR-RS MATE terminals

CRIMP

Crimping terminals

CRIMP

Crimping terminals

Machines, applicators and tools for crimping both cables with insulation and magnet wire

Machines, applicators and tools for crimping both cables with insulation and magnet wire

Tooling

IDC

INAR-IDC RAST connectors

IDC

INAR-IDC RAST connectors

Automatic-semiautomatic machines, mini applicators and tools to process IDC connectors

Automatic-semiautomatic machines, mini applicators and tools to process IDC connectors

INAR-RS

INAR-RS terminals

INAR-RS

INAR-RS terminals

Machines, Insertion Units and manual presses for inserting INAR-RS and INAR-RS MATE terminals

Machines, Insertion Units and manual presses for inserting INAR-RS and INAR-RS MATE terminals

CRIMP

Crimping terminals

CRIMP

Crimping terminals

Machines, applicators and tools for crimping both cables with insulation and magnet wire

Machines, applicators and tools for crimping both cables with insulation and magnet wire

Tooling

IDC

INAR-IDC RAST connectors

IDC

INAR-IDC RAST connectors

Automatic-semiautomatic machines, mini applicators and tools to process IDC connectors

Automatic-semiautomatic machines, mini applicators and tools to process IDC connectors

INAR-RS

INAR-RS terminals

INAR-RS

INAR-RS terminals

Machines, Insertion Units and manual presses for inserting INAR-RS and INAR-RS MATE terminals

Machines, Insertion Units and manual presses for inserting INAR-RS and INAR-RS MATE terminals

CRIMP

Crimping terminals

CRIMP

Crimping terminals

Machines, applicators and tools for crimping both cables with insulation and magnet wire

Machines, applicators and tools for crimping both cables with insulation and magnet wire

Tooling

IDC

INAR-IDC RAST connectors

IDC

INAR-IDC RAST connectors

Automatic-semiautomatic machines, mini applicators and tools to process IDC connectors

Automatic-semiautomatic machines, mini applicators and tools to process IDC connectors

INAR-RS

INAR-RS terminals

INAR-RS

INAR-RS terminals

Machines, Insertion Units and manual presses for inserting INAR-RS and INAR-RS MATE terminals

Machines, Insertion Units and manual presses for inserting INAR-RS and INAR-RS MATE terminals

CRIMP

Crimping terminals

CRIMP

Crimping terminals

Machines, applicators and tools for crimping both cables with insulation and magnet wire

Machines, applicators and tools for crimping both cables with insulation and magnet wire