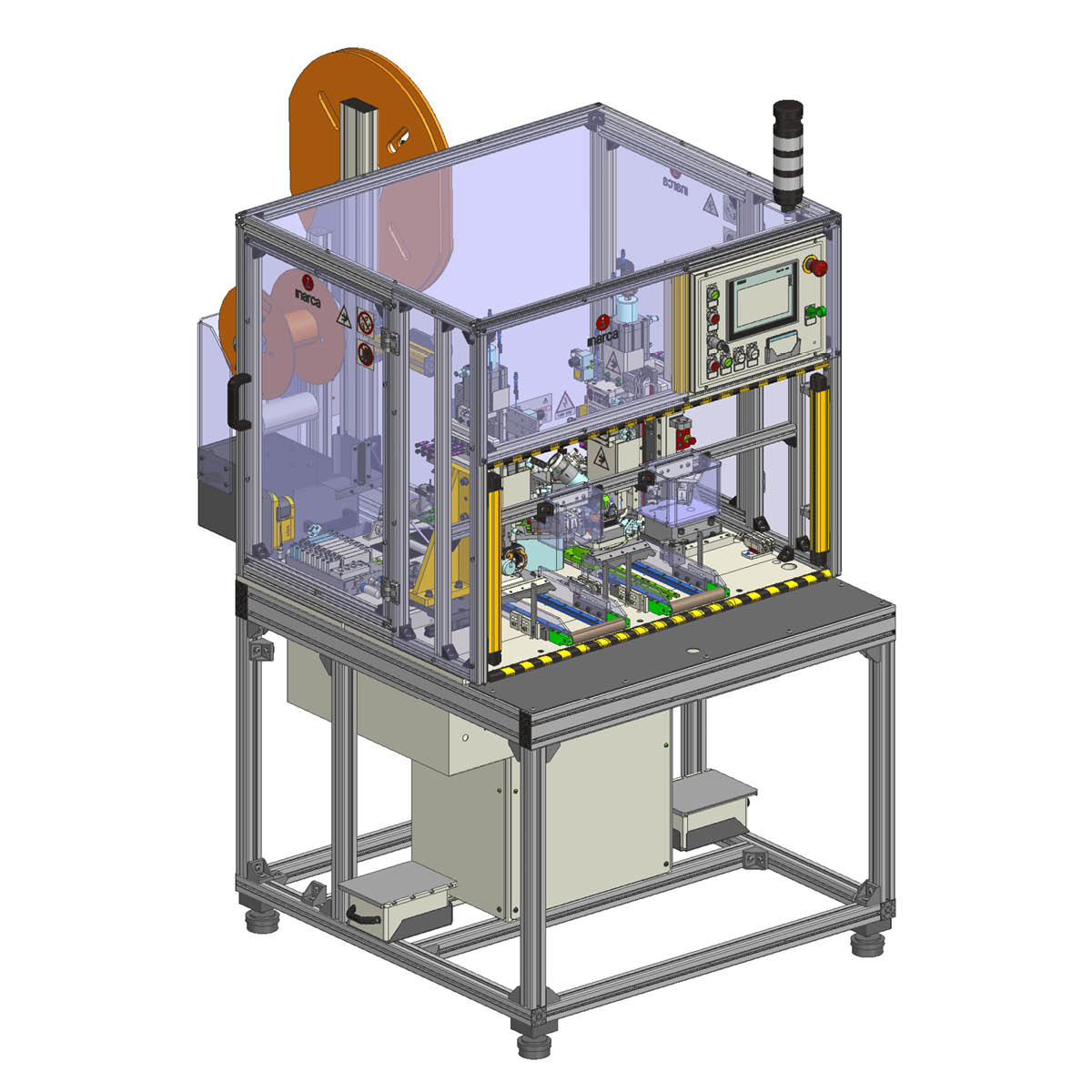

The linear bench machine is a self-contained work island for the insertion (vertical or horizontal) of INAR-RS and INAR-RS MATE terminals in single or multi-way housings arranged in-line. The bench machine can be integrated into an automatic system by adding a manipulator for loading and unloading the workpiece. The workpieces to be processed (stators, coils, etc.) are manually loaded by the operator onto dedicated pallets which take them to the terminal insertion position for connection to the conductor. The terminal insertion unit consists of the M25 A or M25 B assembly (see description in the previous paragraph). The feeding, cutting, terminal insertion and positioning of the terminal insertion unit are fully programmable, whereas the work cycle is started by the operator using a two-handed control. Any machine faults are displayed on the control panel to facilitate troubleshooting and minimise any machine downtime. Wire scraps that are trimmed are collected in a dedicated container. The unit is built in compliance with the strictest accident prevention regulations and ensures optimum efficiency also during prolonged use.

Customers can choose between two versions produced:

M25 1C: with one pallet for loading/unloading the workpiece.

M25 2C: with two pallets to minimise work times since, while one workpiece is being processed, another is loaded onto the pallet.

Technical data:

- Dimensions [mm]: width 900, depth 900, height 1800;

- stator load height: 900.

- Insertion time for every 1.5-second dwell.

- PLC Siemens, programming software with self-diagnostics.

- Touch screen operator panel, MANUAL/AUTOMATIC/STEPPER mode switch.

- Polycarbonate protection at the sides and rear of the extruded aluminium frame.

- Front protection via optical barrier.

- 220V power supply voltage.

- 6 bar pneumatic supply.